Working on an old vintage Omega watch it was apparent that the mainspring needed to be replaced. In fact the old mainspring was not actually broken but very fatigued. It had several ‘kinks‘ in it which can affect the uniform transfer of power through the train of wheels.

The best thing was to replace the old spring with a new one.

In order to do this we must first remove the old spring and measure up. We measure the barrel diameter. In simplest terms, the barrel is a cylindrical container for the mainspring which has a cap and teeth around the edge. We also need to measure the thickness of the old spring, the length and the height. Once this is done we can order the new spring from our watch material dealer. Care must be taken when measuring up – if the new spring is too thick (strong) or too thin (weak) then the watch will not run correctly. If it is too high then it may rub on the barrel cap or we may not even get the cap on.

Many watches will be listed in a special mainspring catalogue called a GR book (generale ressorts mainspring catalogue). This will allow us to cross reference the correct mainspring by watch caliber. The older vintage watches may not have a caliber or may not be listed in the GR book and so we need to measure up.

Once received, we will install the spring and test the watch.

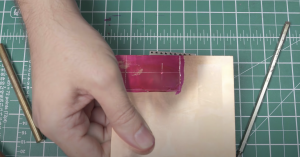

Here we have removed the old spring and cleaned the barrel. From left to right – you see the barrel, barrel cap, barrel arbor (above the barrel cap) and the new mainspring in the red sleeve. The idea is to transfer the new mainspring into the barrel.

There are several ways to do this. It is possible to place the new mainspring (still located in the sleeve) over the barrel and to gently push down around the outer coil of the spring with pegwood until the spring drops into place. Another way (not recommended) is to remove the new spring from the sleeve and wind it into the barrel manually by hand. And finally if the mainspring is out of the sleeve then the recommended method would be to use a professional mainspring winder kit.

A close inspection shows a few bits of debris in the barrel. We need to clean this out completely before installing the new mainspring. If any grit is in the barrel then the mainspring will not last as long and could even break over time.

Modern mainsprings are also known in the trade as ‘unbreakable‘ mainsprings – I do not know why they called them that. I have seen many broken ‘unbreakable‘ mainsprings. They are however extremely strong. It is very hard to break them under normal usage (winding up and letting down). They are brittle because they are made from a hardened spring steel alloy. If they are not cleaned and re-lubricated by a professional watchmaker regularly then they will fatigue and can break over time.

The new mainspring is now in the barrel. We are now ready to replace the barrel arbor into the centre coil of the spring and replace the cap. We will lubricate the arbor bearings and place the barrel assembly into the watch.

The barrel bridge must be replaced and lubricated then we can test the watch. This is most essential – if the spring is too strong the balance will not have the familiar ‘tick tock‘ sound but will have what sounds like extra beats. We call this ‘knocking the banking‘ and basically means the balance is spinning round so far (the amplitude is too great) that the impulse pin starts knocking against another component called banking pins. At some point I will create a glossary with pictures for the most common components in the watch – I appologise for all the jargon. By the way – if the mainspring is too weak then the opposite will occur. The balance will not receive enough power and the amplitude will be too low producing bad time keeping.

Now we have fitted the barrel bridge and the ratchet wheel. As you can see the watch is back in business. Time to regulate and test.