One of the important things to consider when regulating a watch is positional error.

Positional error occurs on mechanical watches and can be caused by many factors. These factors could include a poorly sprung balance spring (out of true), a worn or bent balance staff pivot, not enough (or too much) oil on the balance endstones and possibly the balance being out of poise.

If the rim of the balance wheel has a heavy point then we consider this out of poise.

To test for this we need to use some special equipment – the main tool being the “Poising Tool”. A poising tool is a small bench tool which has the facility to be made completely flat by use of height adjustment screws. The tool will have two adjustable jaws and the balance pivots will be rested upon these jaws.

A high quality poising tool will have ruby jaws and will come with a detachable spirit level. The spirit level is placed on top of the jaws before the balance wheel to make sure the tool is completely flat on the bench.

It is not recommended to purchase a cheap poising tool with steel jaws. We are dealing with a high degree of accuracy here and we should used the best tool that we can afford. I recommend the Bergeon Poising tool with Ruby Jaws and detachable spirit level as shown in the image above.

The idea is simple – you gently allow the balance to rotate on its pivots whilst it is rested on the ruby jaws. The balance will eventually come to a stop and if you repeat this several times and the balance always rests in the exact same position then you have found the heavy point on the balance wheel.

There are a few methods of correcting poise on a balance wheel. The most recommended is to use timing screws if the balance wheel is indeed weight compensated with timing screws. Other methods will be to remove material from the existing timing screws or to remove material from the balance wheel itself. We are talking about extreme finite amounts of material here.

The wheel illustrated here has been weight compensated in the past by having material removed (you will notice many countersinks around the balance rim). We will correct this balance poise using this method.

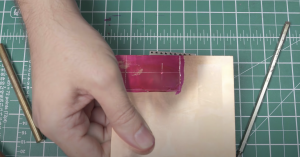

To do this I use a special tool (illustrated above) which cuts material very accurately. It should be noted that anly very very small amounts should be removed from the heavy point on the balance and it should be checked on the poising tool after each tiny cut. Once the material is off – it cannot be replace and if too much is removed then you will find that you will have to compensate for this by removing even more material on the ‘new’ heavy point which will be created on the opposite side.

A balance with timing screws will negate this risk as you will use timing washers which are non-destructive and can be removed if required.

Another point to note is that you should cover the balance when it is on the poising tool as it is very sensitive to small breezes in the room caused by, for example, a workmate walking past your bench.

The image above shows how we can achieve this with a dust cover.

I cannot stress enough that a balance being out of poise is only one possible reason for positional error on a watch and before even attempting poise testing the watch should be cleaned and oiled correctly first.

In my experience I have seen more watch positional errors caused by ill-adjusted hairsprings than the balance being out of poise so all these things have to be looked at.

For a completely in-depth covering of this subject I would recommend “Practical Watch Adjusting” by Donald DeCarle.