This nice old Rotary was handed in for repair with a broken stem and filthy movement. The problem is with the stem. The movement has no calibre and does not appear in any of our reference books so I have no choice other than to make a new winding stem from scratch.

I do this with blue pivot steel. First annealing the steel to make it easier to turn and cut the thread. Here are some pictures of my work.

We have the old broken winder and the other broken piece in the watch. This needs to be extracted so that it can be measured. The watch is in need of a full service in any case so it is stripped completely.

The keyless winding mechanism was over-lubricated – see it has spread all over the movement plate.

So now the stem is extracted from the movement it can be measured. Work gets started on turning the new stem on the lathe. I use a watchmakers lathe for this purpose.

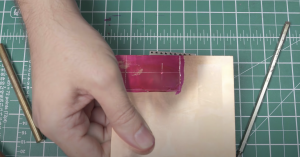

Now the stem is roughly turned out. I have cut the notch and tested it in the movement for size. Now the sliding pinion (next picture shows this on the right) needs to slide onto the stem and the hole is square so I need to file a square on the stem.

Not quite finished but you can see the square forming.

The square is now finished and the sliding pinion fits perfectly. The stem needs to be polished, hardened and tempered. If it is not hardened and tempered then the stem will get damaged very quickly. This is a process where the steel is heated up with a very hot flame until it is a cherry red colour. It then cools slowly. Then it is heated to a cherry red colour once again but quenched fast which makes it as hard as glass, but also very brittle. Because it is very brittle it is then heated slightly to temper (or soften it) to a specific point – this point is reached when the stem turns a nice deep blue colour. At this point it is hard enough for the application but no so brittle that it breaks.

Here we are with the stem complete and installed (the movement is serviced and running very nicely.