Most modern watches will have some form of shock system for the balance. The most common found in the swiss watchmaking industry is “Incabloc” which does a very good job of absorbing shocks caused by knocks or drops.

By the way – for those who do not know, the balance is the spinning wheel which effectively allows the strength to be released from the power source (the mainspring) in a uniform manner. Thus it regulates the watch to put it in simplest terms.

The balance has a spindle running through the middle (think of a spinning top and the point it spins on) which we call a “Balance Staff”. This Balance staff has extremely thin pivots – in this example the pivot is 0.14mm in diameter.

For most modern watches if we come across a broken staff then we would usually contact our material supplier and order a new one. Fitting it is a skilled job but its relatively simple. For many vintage watches it is not that simple – parts are not available and so we have to manufacture a replacement for the broken balance staff.

So we remove the old balance staff and the above picture shows this. Notice the broken pivot on the right.

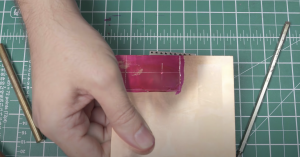

We take measurements using fine measuring equipment then we will use some blue ‘pivot‘ steel in our lathe and start ‘turning‘ the new staff.

As we go along we will place the various components on the new staff to make sure we are on track with our measurements.

The new one is starting to resemble the old.

Here we see the staff is ready for final finishing – we have tried the components and they fit perfectly. From the left wehave the new staff, then the broken one, then the balance wheel, the hairspring and the roller. We shall fit the balance wheel first as this will aid us with using the Jacot tool for polishing the pivots.

This part is not particularly exciting – we spend some time polishing the pivots with a burnisher and this Jacot tool.

Now we do not want the ends of the pivots to be dead flat – we want them slightly rounded on the edges. We have a tool for that and so we spend some time doing this. A little diamond powder and oil mixed into a paste helps us.

Now we assemble the balance ready for fitting back onto the watch movement. The above picture shows us using a staking tool to safely fit the roller onto the balance – this is fairly tight fitting and the tool helps us drive the roller down without damage.

We have now assembled the balance.

The balance is now fitted back into the watch – now we just need to tweak, regulate and test the watch.