WATCH FAULT FINDING

OVER 4 and a half HOURS OF CRYSTAL CLEAR HD VIDEO TEACHING

GET INSTANT ACCESS

Level 3 – Fault Finding

- Enrollment Cost

- COURSE ACCESSYou get immediate access to the course material including the HD resolution video lessons and no time limits.

- NO LIMITSYou can review all the material, including the videos, as many times as you wish.

- COURSE EXPIRATIONAccess to this course does not expire!

Get this course level even cheaper - its included in our...

Getting Started Bundle

What you will learn in Level 3

IN ORDER TO SUCCESSFULLY DIAGNOSE FAULTS WITHIN A WATCH MOVEMENT, YOU NEED TO FIRST UNDERSTAND HOW IT OPERATES

Level 3 Course Content

c3.0.0 Introduction

This video lesson serves as an introduction to Level 3 and introduces the topics being discussed.

c3.1.0 The Initial Inspection

When you receive a watch for service or repair, you may be given an indication from the owner of the watch as to the symptoms of the fault. And this information can help you zone in on the cause. The topics within this level will discuss the initial inspection of the watch movement.

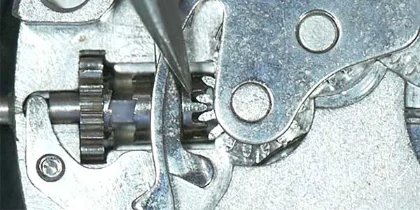

c3.1.1 Check The Motion Work

Checking the hand setting mechanism is an essential step when you are performing your initial inspection.

c3.1.2 Check The Keyless Work

In this lesson we look at some initial tests with the winding mechanism.

c3.1.3 Check Bearings & Pivot Holes

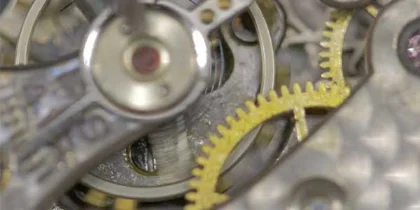

In order for the train of wheels to turn smoothly and uniformly the pivot holes (or jewels) need to be in perfect condition.

c3.1.4 End and Side Shake

c3.1.5 Check The Balance And Escapement

Continuing with the initial inspection of the watch movement, this lesson focuses on the Balance and Escapement.

c3.1.6 Summary

This video lesson serves as a summary of the above lesson topics.

c3.2.0 Fault Finding Pathway

c3.2.1 The Strategy

This lesson contains a breakdown of the strategy behind the Fault Finding Pathway including some demonstrations on how to implement your checks.

c3.2.2 Practice

c3.2.3 Performance

c3.3.0 Testing The Escapement

After performing the initial inspection, if the cause of any faults was not detected then we should proceed with fault finding and we shall start with the balance and escapement.

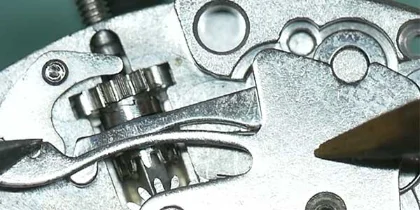

c3.3.1 Pallet Banking

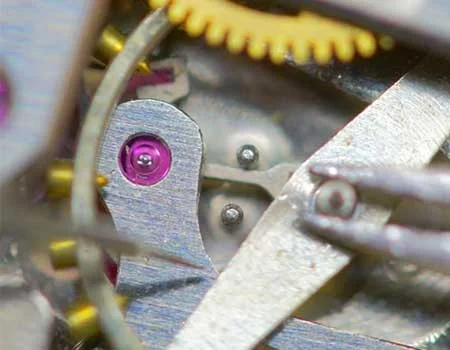

In this lesson we will be focusing on pallet banking and the amount of shake (or distance) between the guard pin and the safety roller.

c3.3.2 Drop, Draw To Lock and Impulse

In this lesson we are looking closer at the operation of the pallets as they interact with the escape wheel.

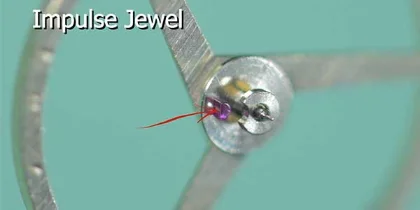

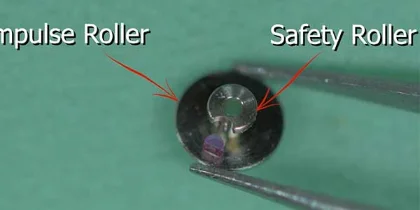

c3.3.3 The Escapement Parts

In this lesson we are taking a closer look at the parts which make up the escapement.

c3.3.4 The Balance Wheel And Staff

The balance wheel is just that, a wheel which is balanced in it’s weight when it is first manufactured so that there are no heavy spots, the balance wheel is riveted to the balance staff.

c3.3.5 The Hairspring

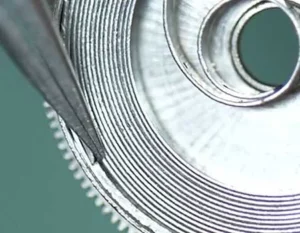

The hairspring is a very fine flat spiral profile coil made from metal, the length and thickness of which affecting the oscillations of the balance wheel.

c3.3.6 The Roller

This video discusses the safety roller and how it plays a roll in keeping the watch movement running.

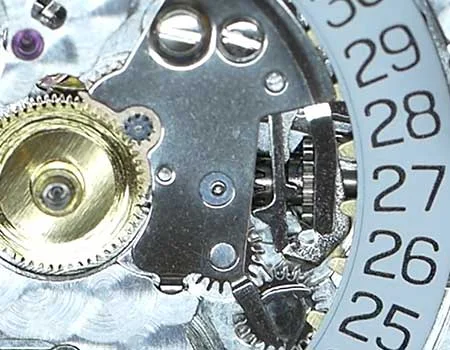

c3.4.0 Train And Power Source

c3.4.1 Power Retention

c3.4.2 The Mainspring

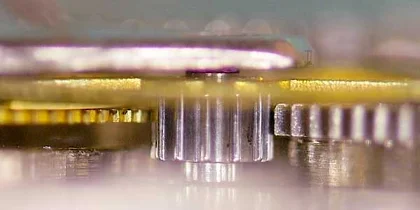

c3.4.3 Train Speed

c3.4.4 Investigating The Train

In this video lesson we are taking a look for potential problems with the train.

c3.4.5 End & Side-Shake

In this lesson we take a look at the train wheels and demonstrate how we can adjust end-shake by using a jeweling tool.

c3.5.0 Keyless & Motion Works

c3.5.1 Problems With Winding

c3.5.2 The Setting Lever Spring

c3.5.3 Rough Winding

c3.5.4 Problematic Hand Setting

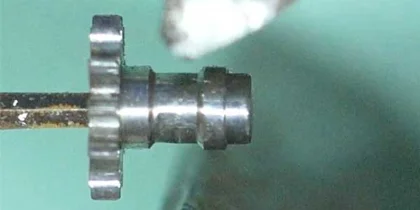

c3.5.5 The Cannon Pinion

This video lesson discusses the cannon pinion and how it can affect the movement should it not be adjusted correctly.

c3.6.0 Summary

This video lesson follows the Level 3 assessment and summarizes the topics discussed.

Recent Reviews For Level 3

Level 3

Mark this level as helped me in more ways then i can think of its shows how quickly it is to find and resolve faults which i would of been…

Well worth the time and effort and price.

Information was detailed yet concise. Sections were well planned and helpful in solving a current issue I had. That alone was worth the price of admission.

Phenomenal

I have to say that this particular course is the reason I chose to learn from Mark. Understanding all the components of a watch and how they work together is…